Intelligent manufacturing decision making: avoid these three value-destroying behaviours

Mounting performance pressures on manufacturing companies globally has increased the urgency for smarter manufacturing decision making, particularly in high labour cost countries such as Australia. The list of issues plaguing manufacturers is daunting: intensifying global competition, reducing technical resources due to ageing population, industry consolidation, stricter environmental regulations, higher raw material costs, plummeting product life cycles, and increasingly demanding customers and shareholders are just a few of the pressing concerns.

These broad-ranging factors represent areas of continuous improvement focus for manufacturers to ensure they survive and thrive. Innovation is occurring rapidly and the Industrial Internet of Things, device connectivity, big data, virtualisation and other trends are tackling these challenges from a range of different angles.

But what about some lower hanging fruit? There are plenty of ripe opportunities in most manufacturing environments for better manufacturing decision making, particularly in smaller tier companies.

When we visit factories, we often see behaviours that destroy value, both on the production floor and in the planning processes for operations. In this blog, we will explore three value-destroying behaviours that I believe – should they be resolved – can provide continuous improvement in manufacturing.

1. Value-destroying behaviour between siloed operations

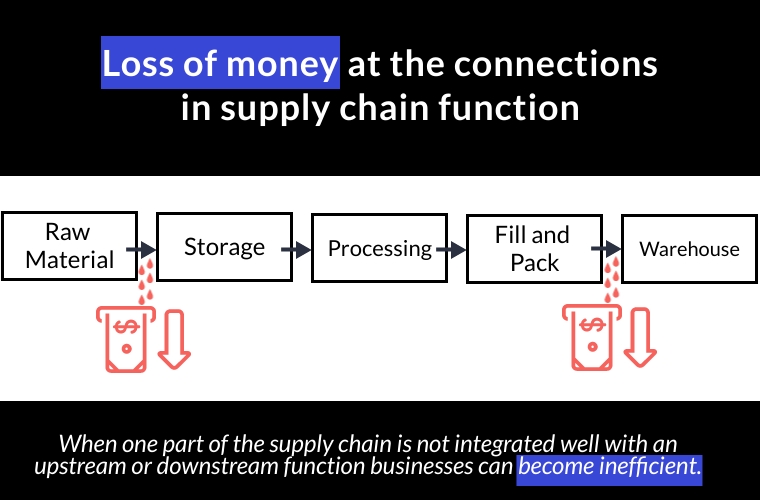

For most manufacturers, supply chains are split up into silos for geographical, regulatory, commercial or complexity reasons. These silos can exist over large (global) or short (metres) physical distance or be completely virtual. Every manager is different and will have a unique way of running operations.

When operating on closely linked silos, this has the potential to be detrimental to overall productivity, as often managers between siloed operations will work toward misaligned KPIs. Production decisions are made in isolation without understanding the impact on the performance of the overall system. Unified KPIs are often lacking, and optimal performance of one silo can destroy value in another. Decision-makers are happy to "settle" for what a precursor silo tells them and make suboptimal decisions without sufficient tradeoff analysis based on metrics and facts.

A classic example is the walls put up in a process industry, such as dairy. Raw material management (intake) does not sync with what is best for the processing facility, which in turn does not fully model the dynamic with warehousing, inventory, and outbound logistics.

This becomes more complex in a multi-plant regional setup.

Often value is lost between supply chain functions where poor communication results in a lack of synchronisation.

These relationship dynamics drive the requirement of integrated value chains though often the problem persists, even with aligned systems, processes and metrics. We hear time and time again that it is difficult to manage complex operations at the required level of detail, particularly considering the dynamic nature of near real-time requirements across manufacturing processes.

2. Value leaks within manufacturing process areas

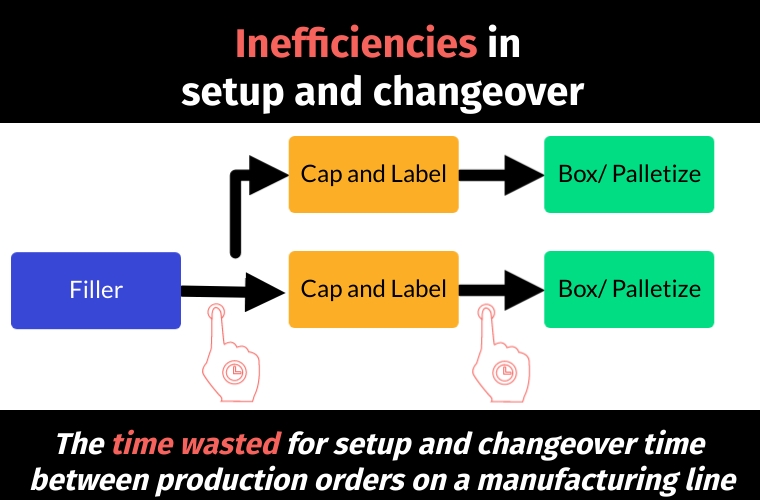

Drilling down a little deeper, between individual manufacturing processes or machines, the sequencing of orders and associated routes can quickly multiply to be an enormously complex problem. Optionality can be mind-boggling, and we often see planners and schedulers resorting to their own personal philosophies on how to schedule.

This results in status quo embedded business processes that cause re-enforcement through stubborn repetition: "I always schedule that Product/SKU using that route because...”.

Complex setup and changeover relationships between different products or processes can result in inefficiency.

Often, a traditional response may very well be the best, but if we are not continually challenging, simulating and assessing alternate operating strategies, how do we really know?

Let’s look at an example from a manufacturing process area

An example of this behaviour was exposed recently where a production scheduler was responsible for managing a complex 10-line environment. They did a great job sequencing production orders in a multi-million-dollar enterprise with the finite capacity scheduling software system from an ERP provider. Orders were dutifully placed on lines, constraints were managed, and there was a dynamic interplay between staff, including system interaction, verbal discussion and production meetings prior to committing the schedule.

However, when we looked in detail, there were a couple of red flags.

Resource and route capacities were set once a year based on financial budget models and there was high variation between expected run times and actual. OEE metrics looked great and the team felt the job was being done well - schedule adherence was almost always positively skewed (a strong leading indicator that there is nothing major wrong) and changeover times were static and always within spec.

Imagine though, the scheduler creates a conservative schedule, but it is based on conservative modelling of actual capacities; not updated regularly enough.

The operators receive this easily achievable schedule, complete each order, look at the expected change over time and, perhaps, use this time between operations to work on other pressing duties. Before you know it, you have a cascading and accumulating inefficiency that is difficult to measure in the defined KPIs. A rigorous focus on actual to-plan performance and utilising real-world operational data to update the tolerances on decision models can reduce costs or provide huge latent capacity.

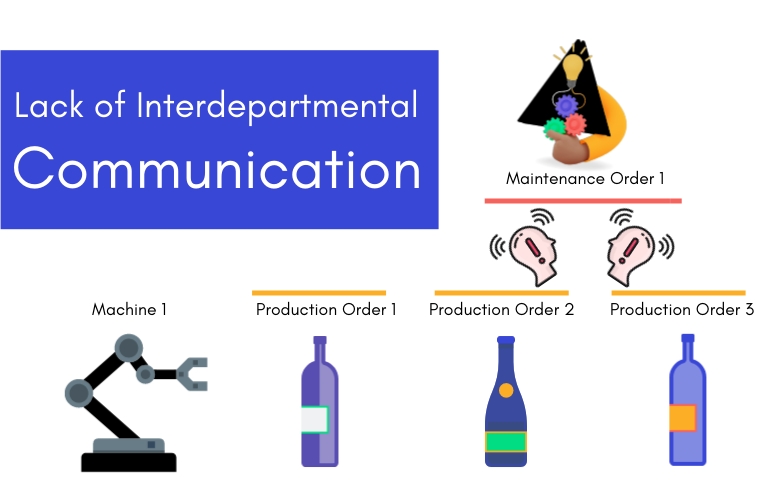

3. The outdated balancing act of production vs maintenance

Departmental walls are commonplace. The one I see most often is the systematic lack of robust collaboration between production personnel. It is rare to see a completely integrated production and maintenance scheduling and execution system, balancing the most efficient, cost-effective and proactive maintenance strategy against the all-important production impact. And then executing the operators to carry out the tasks when they should be to ensure schedule conformance.

We hear a lot of rhetoric about carrying out maintenance at end of shift times or waiting until the weekend to perform cleans/changeovers/maintenance tasks. When asked how management know if that is the best time to carry out this work, the answer invariably is “they don’t”, and it was “a call made by the business to run that way”. Furthermore, there is no way to inform management if the job was done, and when it was done.

Manufacturing requires visibility and integration across departments such as production and maintenance to ensure efficient operations.

Why don't manufacturing systems integrate seamlessly? System integration technologies are vastly superior and more efficient than even five years ago. Is it too much to ask that the production scheduling system has real-time visibility into the current planned or required work against each resource and that the production scheduler and maintenance planner can run multiple what-ifs to determine “best time” outcomes? Phone calls, distributed spreadsheet reports and arbitrary judgement calls are still omnipresent, and they do not need to be.

The way forward: intelligent manufacturing decision making – it’s easier than you think!

We see investment in a few key areas as critical for enabling quick operational improvement without jumping on the latest trend or cutting-edge technology.

Understanding manufacturing plant performance, measuring downtime, modelling appropriate OEE metrics and implementing processes to improve these is critical. It is important to ensure that operators cannot adjust the numbers – a possibility when using paper-based systems – which requires the use of automated data capture systems to produce verified and accurate production metrics. Then, businesses can use this information to continuously validate decision making systems such as Master Production Scheduling, Detailed Scheduling and Execution tools ensuring the data is reflective of what is happening on the shop floor.

The barriers to entry for these capabilities have traditionally been high (i.e., expensive with significant ongoing management), but innovative and disruptive technology vendors such as TilliT are rapidly reducing the price point and ease of integration, taking away market share from expensive providers and systems integrators who thrive on long, complex, and drawn-out projects for deriving revenue.

Chat with our friendly TilliT team and learn how to improve your operation within days.

Enjoyed this post? Don't forget to share!