Beyond OEE: The Digital Maturity Journey Toward Frontline Digital Operations

John: "Entering the second year of my digital transformation journey has been a rewarding experience, commencing with the integration of all our production lines and the implementation of a sophisticated digital system. This innovative approach has granted us real-time visibility into our Asset Performance and Overall Equipment Effectiveness (OEE) and the specific reasons behind any downtime events.

IoT devices helped our team increase our OEE figures dramatically with a 22% improvement within 9 months. This achievement surpassed initial business expectations, which anticipated a 15% increase over the first 12 months but we are now witnessing a plateau and further improvements have become elusive. A closer examination of our action plans reveals a recurring theme—operator training is an ongoing challenge given our turnover rate of approximately 30-40%. The need for re-training is almost as frequent as our efforts to onboard new staff, posing a continuous hurdle in sustaining and advancing our operational efficiency. We just can't keep the domain knowledge long enough."

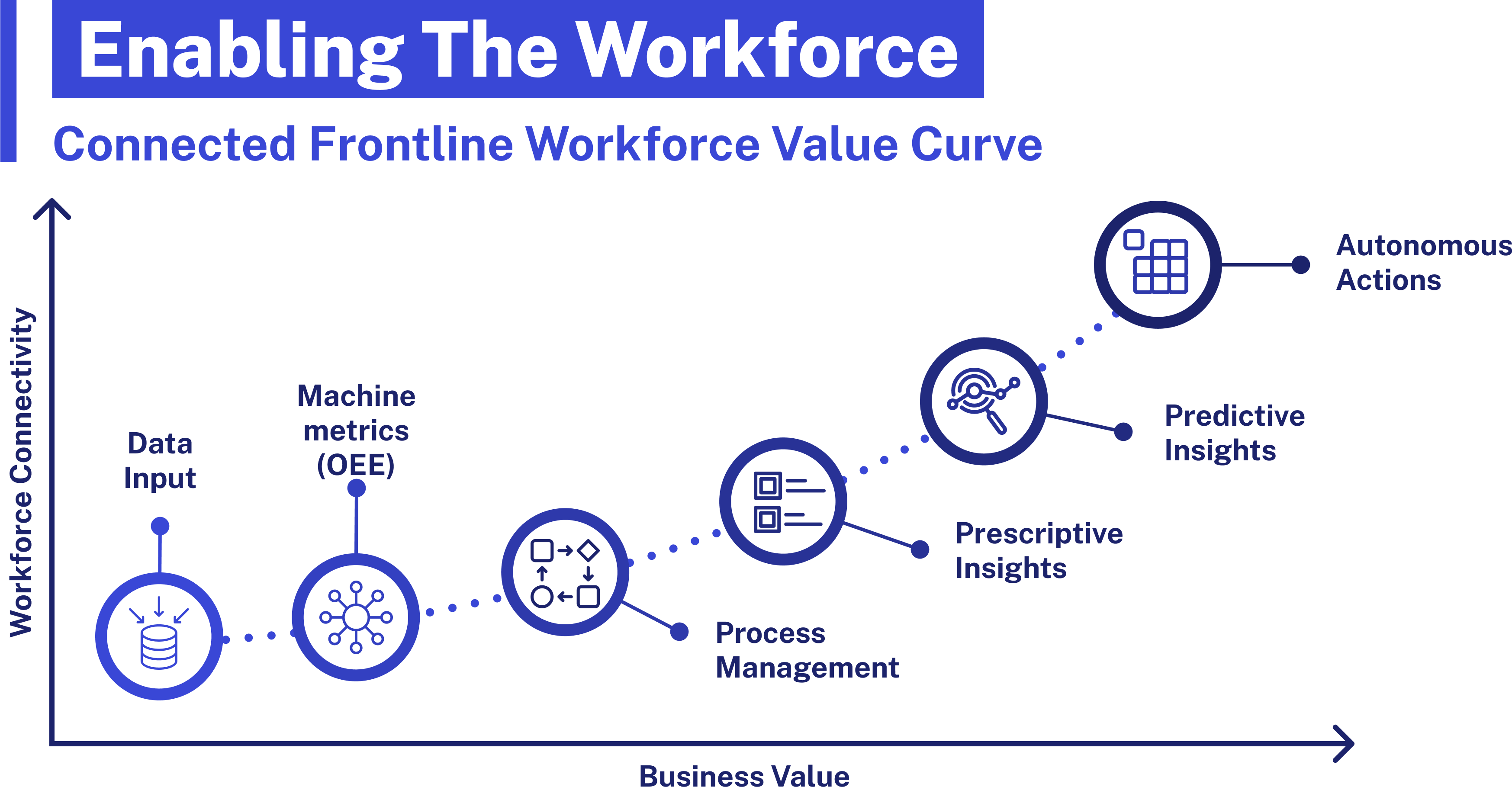

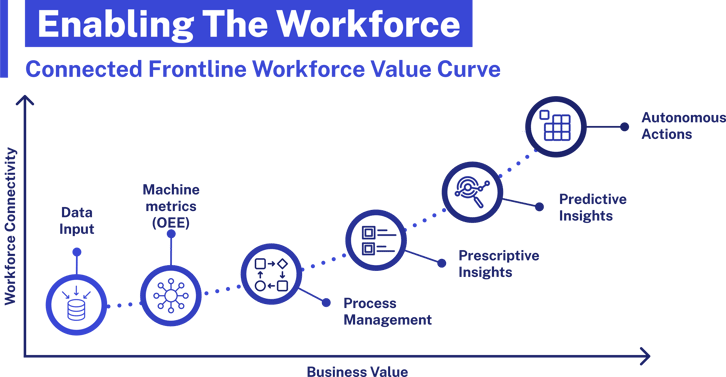

The paragraphs above capture the sentiment echoed by numerous companies we engage with who've successfully navigated to level 1 in their digital journey. OEE stands out as a great entry point, ushering companies away from the antiquated, disconnected, analog and paper-based approach to factory management. However, a prevalent trap lies in perceiving OEE as the sole solution leading to operational excellence.

OEE operates as a key performance indicator (KPI). Its calculation involves assessing equipment availability (actual working time divided by the expected working time), performance (the ratio of actual production speed to the optimal production speed) and Quality (percentage good parts). Frequently, OEE is paired with Downtime recording, offering a means to compile a Pareto analysis of reasons for operational under-performance. It is however usually skewed towards equipment and asset information. While it excels at capturing what occurs with the machinery, a manufacturing facility operates as a network of interconnected nodes, transforming raw materials into finished goods and may miss a broader perspective.

The stakes are high in John's factory with the staff turnover, where even a single mistake – be it following the wrong procedure, using the incorrect raw material, or skipping a critical step in the process – can translate into substantial financial losses, ranging from tens to potentially hundreds of thousands of dollars for one issue.

Facing the limitations of his initial approach, John recognizes the need for a more human-centric solution. In his desperation, he turned to HR, who responded by revamping outdated training videos and refreshing the 75-page standard operating procedures (SOP) that had accumulated dust over time. However, these efforts haven't yielded significant improvements so far.

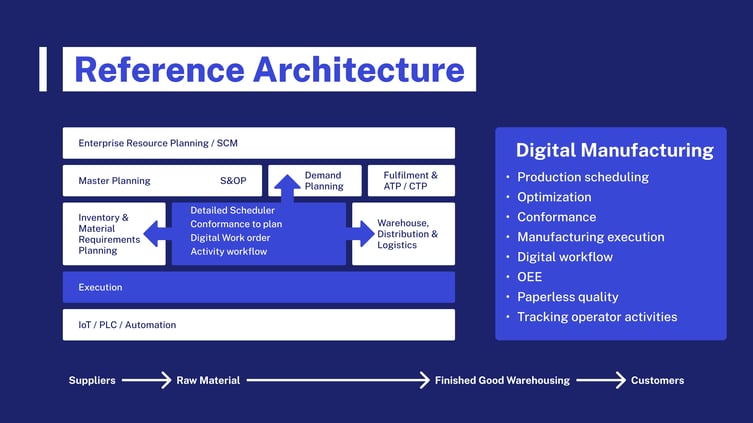

John has come to the realization that he doesn't require another reporting system, Manufacturing Intelligence System (MIS), or Manufacturing Execution System (MES). What he truly needs is a Manufacturing Digital Operations (DO) approach. While the acronym might not be industry recognized, the essence is serious – John seeks a holistic system that goes beyond monitoring and reporting, aiming to seamlessly manage and optimize the entirety of his manufacturing operations.

Unlike traditional systems, digital operations place the frontline worker at the center of the approach. It revolves around the perspective of the operator, providing assistance throughout the end-to-end manufacturing process. This includes crucial steps such as preparing and loading raw materials, configuring machine parameters, conducting quality checks, performing maintenance activities, cleaning, and more. By focusing on the operator's perspective, DO aims to enhance efficiency and effectiveness at every stage of production, addressing John's critical need for staff knowledge and performance improvement.

Let's look at Emily, who has been operating at level 2 for a few months now after a strategic decision to accelerate their digital strategy, and observe the substantial benefits and gains she's experienced. As the Quality Manager of a wine-making facility, Emily plays a pivotal role in ensuring that the shipped products undergo rigorous quality assurance steps.

The rationale was clear – by setting up the manufacturing workflow and connecting the machinery with a Digital Operations approach, OEE would be automatically calculated as part of the process. The recording of downtime reasons seamlessly integrated into the system, treated as just another operator activity.

Today, thanks to the implemented system, Emily can confidently scrutinize a specific work order, ensuring that every step has been meticulously executed. In the realm of wine production, which has a lot of similarities with most food and beverage processes, a standard batch involves up to 200 intricate steps, each reliant on the operator's precision, timing and knowledge.

Previously enabled by paper and custom systems, an operator had to rely on a 75-page SOP and memory, determining each moment's production requirements. Missing even one of these 200 steps posed severe risks, from potential audit complications to jeopardizing certifications. The consequences of a skipped step were dire – it could lead to undetected production failures, resulting in rework, scrap, or, in the worst-case scenario, a flawed pallet sent to a customer. The cascade effect could trigger recalls, customer complaints, a manufacturer's worst nightmare.

The Digital Operations system intelligently feeds the necessary instructions precisely when needed. The operator is presented with a simple screen displaying one to several activities at a time. Every activity within the system is encapsulated in a an intelligent digital form. These forms serve as comprehensive guides, clearly instructing the operator on the necessary steps. As the operator progresses through the tasks, they input responses to any questions posed by the form. Crucially, the form acts as a double-check mechanism, verifying the accuracy of the operator's work.

In the event of a control process deviation, the system promptly issues a warning to relevant stakeholders. With this real-time oversight, corrective actions can be swiftly implemented in near real time, mitigating risks associated with quality deviations and reinforcing the overall integrity of the production process.

The process remains unchanged, with the system now serving as a co-pilot, seamlessly assisting the operator at every juncture. Similar to the guidance you'd receive from Google Maps, Apple Maps, or Waze, the system offers step-by-step instructions, ensuring a foolproof journey through each activity.

The process remains unchanged, with the system now serving as a co-pilot, seamlessly assisting the operator at every juncture. Similar to the guidance you'd receive from Google Maps, Apple Maps, or Waze, the system offers step-by-step instructions, ensuring a foolproof journey through each activity.

Taking innovation a step further, Emily's company leveraged the Digital Operations system to seamlessly orchestrate activities across different silos through digital messages. With a single laboratory serving all seven bottling lines, managing samples and ensuring accurate linkage to the right production order presented a considerable challenge. In the past, this was handled using traditional post-it notes or hand written forms. Now, the operator utilizes the system to print a detailed lab label, affixing it to the sample bottle, while the laboratory concurrently receives an activity notification to expect the incoming sample.

The game-changer here is the implementation of QR codes. By scanning the labeled QR code, Emily's team ensures the maintenance of a robust chain of custody and traceability for this crucial component of the production process. From batch readiness through to hand off to the outbound supply chain, Emily knows every aspect of her operational contribution to the total cost of goods.

Emily's journey through the digital transformation exemplifies a paradigm shift in the approach to manufacturing excellence. Aside from the efficiency and quality improvements she achieved a reduction in staff turnover from the industry norm of >25% pus to less than 15%. Critically, the time taken to train staff in the myriad of rules, processes and procedures was reduced by 80% from 3 months to approximately 2 weeks greatly improving training and recruitment budgets and freeing up key knowledgeable staff to work on optimizing plant operations.

This journey underscores the broader potential of Digital Operations systems in fostering an holistic approach to digital operations. As businesses navigate the complexities of modern manufacturing, it becomes evident that a comprehensive system like TilliT, which prioritizes the frontline worker's experience, can not only resolve immediate challenges but also pave the way for sustained operational excellence.

Enjoyed this post? Don't forget to share!