Integrating artificial intelligence in business – bridging the gap to real world application

In the field of big data and analytics (BDA), artificial intelligence (AI) reigns supreme. Yet, despite AI having such a significant presence in the professional landscape – with research, industry, venture capital and consumers consciously (or unconsciously) investing in its use – it remains one of the most misunderstood capabilities of the analytics field.

It stirs a range of emotions for those not well versed in the technical detail of what AI really means. What makes AI confusing is the breadth and complexity of its methods. It is both pervasive in areas such as search, and in its infancy in many suitable commercial domains.

All business sizes can benefit today from some form of sophisticated data modelling. Although AI is technically complex, it can be understood simply as the growing ability of computers, using advanced algorithms, to recognise patterns and to make logical inferences1. Think about that. By taking a particular problem in your business that has sufficient data, you can simply create a model of the problem and use an algorithm that fits into the classification of AI to help create possible answers to the problem and, hey presto, you are using AI!

But is it really AI? It is worth explaining the differences in AI approaches to real-world problems to help cut through the confusion.

Traditionally AI has been split into two broad categories of application and associated technique:

-

Artificial general intelligence

-

Applied artificial intelligence

Artificial general intelligence (AGI)

Artificial general intelligence is simplified to describe the strain of AI focussed on human-like reasoning. This historical pure AI research goal tries to mimic human behaviour and aligns most closely with the “robot taking over the world" belief.

While certain researchers define this as pure AI, it remains an elusive and very difficult goal with existing technologies available to achieve true human-like reasoning, interpretation and emotion. Interest has waxed and waned over the last five decades – at times, blossoming into commercial realms – but mostly remaining confined to dedicated researchers in confined environments.

Robots won’t be “taking over the world” any time soon, but AGI mimicking true human behaviour is edging closer to reality.

Robots won’t be “taking over the world” any time soon, but AGI mimicking true human behaviour is edging closer to reality.

However, today, there has been a renaissance. The ecosystem of research, application and supporting computational power has grown to the point where there is a real chance momentum will deliver something close to the original goal in the coming decade or two.

Applied AI

Applied AI is the application of AI techniques and computer algorithms to model and solve specific problems or to discover hidden insights in data. Approaches such as machine learning, expert systems, inference engines, and pattern recognition (e.g., speech, voice, text and image recognition) expressed through interfaces such as Microsoft Cortana, Apple Siri and Google Tensor are all examples of applied AI.

These most recognised BDA techniques and AI approaches can2:

-

Observe past user interactions and other user behaviour

-

Gather sensory and semi-sensory inputs, such as the user’s geolocation and weather conditions, and the user’s body temperature, heart rate, etc.

-

Ask the user for additional information, feedback, or clarification

-

Access additional data, and apply additional algorithms

-

Store all the above as an always up-to-date user profile

Enormous investment is going into these areas of AI research and the commercial application for consumer and business needs.

Artificial intelligence in business

Applied AI includes the utilisation of computer algorithms to solve real-world business needs such as a manufacturing challenge of determining which product to bring to market next, based on consumer demands.

The specification and application of a range of algorithmic approaches to well-defined problems have absorbed most of the effort in using AI in the past 30 years. Examples include metaheuristic and hyper-heuristic techniques combining optimisation approaches such as evolutionary computation (genetic algorithms), particle swarm intelligence and simulated annealing – applied to logistics, scheduling, and sequencing type problems in business.

The application of these optimisation techniques will only increase as the capability moves from limited research to real-world use by technology providers specialising in AI.

Applied AI can be utilised to solve real-world problems, including complex planning and scheduling issues on the manufacturing line.

All planning and scheduling tools used in business today are simplified representations of the real-world environment they are supposed to represent. This is acceptable, as there is always a trade-off between model accuracy (resolution) and the processing time they take to perform a function (e.g. change the order of a series of production orders or optimise a particular time period).

With advances in computational power, the models we can create to simulate real-world possibilities are improving greatly, and big data is a key enabler of superior business outcomes.

Why local, regional and global companies should be thinking about AI

As our understanding of applied AI improves and traditional computational processing power constraints relax, more businesses are looking to AI to gain a competitive advantage.

The reality is that most businesses today have not assessed or adopted these approaches to continuously improve their efficiency. There is often more algorithmic power in the mobile phones carried by each employee than the organisation utilises to assist in making better business decisions.

Spreadsheets are often still the de facto decision-making toolset as they are cheap, flexible, difficult to remove or replace, and empower conventional knowledge retention. A spreadsheet may represent an acceptable framework on top of which AI techniques can be applied but maintaining and scaling those solutions is difficult.

Frost and Sullivan3 summarise why businesses should be taking AI very seriously. Consider these three scenarios:

-

AI’s powerful inference and pattern recognition capabilities could improve the speed, efficiency and effectiveness of almost any legacy automated system. What other improvements might an intelligent system in the middle of a legacy environment suggest, or require? How will organisations sort out the many new ways in which these augmented and autonomous systems might interact, and choose the best configuration?

-

Text and image-based AI solutions could put pertinent information at the fingertips of low-level personnel, as IBM’s Watson is doing already in some retail applications. If these employees have well-guided access to complete product and service information, they will not need to escalate customer requests or ask their managers for assistance. This will speed customer service and save companies money; but how will this affect the now unnecessary product specialists and managers, and the rest of the organisation?

-

AI-based applications could optimise the value chains of industry, eliminating waste, and speeding up product and service deliveries. But whose priorities will drive these improvements? How will multiple entities cooperate to achieve overall optimisation objectives? AI research and application development are advancing rapidly; and business decision-makers need to be paying attention to these developments, engaging AI-enabling software companies that can offer a highly differentiated platform for decision making.

TilliT and BDA – understanding the real-world application of artificial intelligence in business

TilliT is a no-code, simple to set up, digital factory platform that provides a point of difference SaaS and IoT solution to manufacturers. The powerful, yet simple to implement, digital factory suite provides an integrated way to plan, execute and analyse manufacturing processes by orchestrating people, machines, material and tasks – all in one out-of-the-box cloud application.

TilliT has been designed as a do-it-all digital platform, focused on deriving the maximum benefits of big data analytics to drive the decision model. Big data from manufacturing and industrial automation systems – combined with predictive analytics – can expose powerful trends, relationships and metrics (manufacturing performance analytics) to then feed constrained dynamic models for production optimisation purposes.

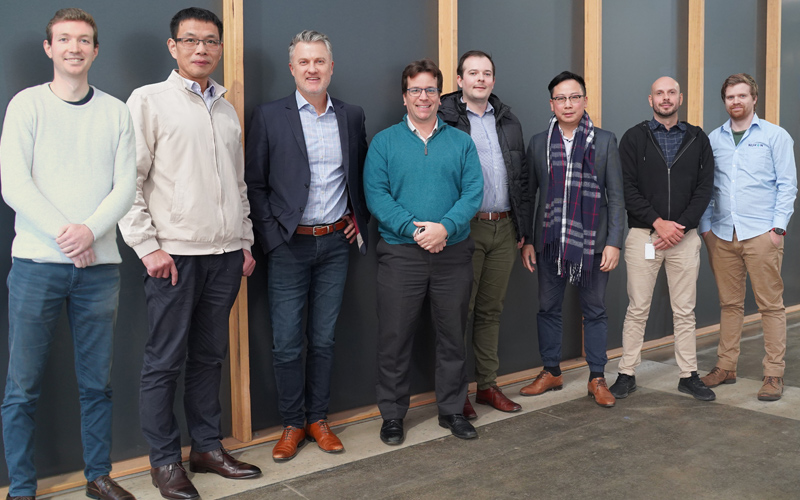

The TilliT team consisting of (from left): Brodie Moran, Weidong Fang, James Balzary (Co-Founder & CEO), Rafael Amaral (Co-Founder & CTO), Devin Reeks, Alvin Yim, Gui Keller and Kieran Waller.

The TilliT team consisting of (from left): Brodie Moran, Weidong Fang, James Balzary (Co-Founder & CEO), Rafael Amaral (Co-Founder & CTO), Devin Reeks, Alvin Yim, Gui Keller and Kieran Waller.

This approach can make the underlying model being used as close to the real world as possible before invoking AI, or other prescriptive analytics to run modelled simulations on what is best for the given business objective or KPI. The combination of big data analytics, accurately constrained simulation and advanced optimisation represents a next-generation approach to supply chain efficiency.

Ask us how TilliT can increase the visibility of your asset and manufacturing line performance, direct the execution of events and coordinate activities necessary to manufacture any type of finished good, using one, affordable, pay-as-you-go solution.

1 Frost and Sullivan - Artificial Intelligence - A Practical Assessment. 2015.

2 Frost and Sullivan - Predictive Analytics in the Real World. 2015.

3 Frost and Sullivan - Artificial Intelligence - A Practical Assessment. 2015.

Enjoyed this post? Don't forget to share!